🎣 2026 Freight Predictions (Print Preview)

A preview from FreightCaviar Print. December copies are still available.

Named after the Greek goddess of victory, Nike, founded around 60 years ago, is the world's largest athletic footwear and apparel manufacturer.

Did you know that the company's original name was Blue Ribbon Sports?

The journey began in the trunk of a car, and today the company owns the Air Jordan, Converse, and Hurley brands.

Today, we'll delve into Nike's supply chain and sustainability.

Note: I have no affiliation with Nike and do not benefit financially from this article. I created this article out of pure interest in the company and yeah the Air Jordan's in the photo are mine.

Just Do It

Nike manufactures 26 pairs of shoes every second; an incredible 800,000,000 pairs in 2023.

68% of the company's $51.36 billion revenue comes from footwear, with 95% coming from shoes and apparel. The company's supply chain strategy is to almost entirely outsource production to countries where wages and costs are significantly lower than in Western countries. This has enabled Nike's success from the beginning and allowed the company to focus its energy on product development, marketing, and distribution.

Diversifying suppliers across multiple countries has improved the company's resilience. A key goal of the company is to build strong partnerships to ensure the effectiveness of outsourcing. Partners have clear standards, performance metrics, and incentives to support success. Decision-making focuses on continuous learning, advanced analytics, and creating the best possible demand forecast. It is important to note that Nike's supply chain is constantly evolving.

The company faces challenges such as geopolitical risks, economic fluctuations, and changing consumer preferences. However, its core principles, such as outsourcing, diversification, data-driven decision-making, and a focus on speed, flexibility, and sustainability, have been key to its success. Even a large vessel must adapt quickly to consumer trends and volatile market conditions.

Looking at the big picture, the company's materials are produced in 13 different countries and 123 factories. Finished products are made in 36 countries, 500 factories, and by 1,133,385 employees. From there, the journey continues to 50 distribution centers and over 100,000 retailers.

You can learn more about the factories by following this link:https://manufacturingmap.nikeinc.com/

During the COVID-19 pandemic, Nike observed a 75% increase in sales through its own sales channels. This led the company to significantly reduce the number of retailers and limit the product range that retailers could sell. Several stock analysts have written columns criticizing this decision and seeing it as one reason for the company's recent poor performance. They argue that people still want to try on shoes before buying them online and that retailers serve as important showcases for Nike products. For example, the Motley Fool has an article providing a 5-year outlook on Nike stock:https://www.fool.com/investing/2024/07/14/where-will-nike-st... For this reason, Nike has pivoted to a direct-to-consumer strategy. They have brought back several retailers as partners and reopened the product range. In addition, the company is focusing on reducing inventory values and improving social responsibility and sustainability at factory locations.

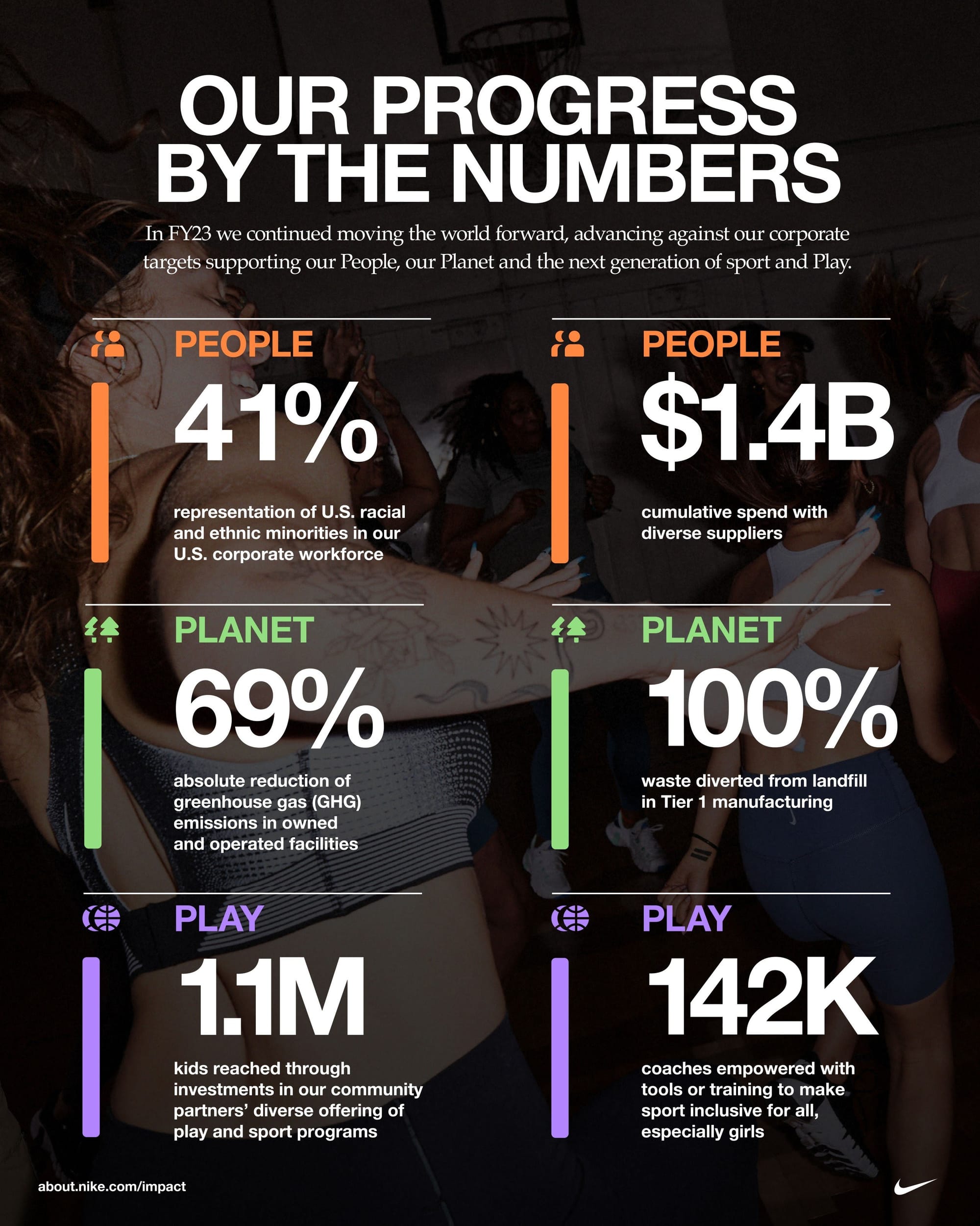

Sustainability Results From The Financial Year 2023

Join over 14K+ subscribers to get the latest freight news and entertainment directly in your inbox for free. Subscribe & be sure to check your inbox to confirm (and your spam folder just in case).