🎣 The Perfect Stolen Load

Plus: backlash over carrier safety rankings, the Port of LA’s push toward 10M TEUs, states expanding ICE enforcement, and more in today’s newsletter.

Imagine that the 2024 season will feature a record-breaking 24 races across five continents.

Each team has around 4 to 6 race sets available. Spare equipment can be shipped in containers, for example, from Japan to Montreal, reducing the use of air freight.

Teams typically have seven hours after a race to pack their equipment to make it on time for the next race. Later leaving shipments will also arrive, but they will

travel via commercial air freight.

Notably, DHL has been the main logistics provider for the F1 series for the past 20 years, and the company has a contract in place for the next 9 years.

Independent teams have the right to choose other providers; for example, Ferrari works with CEVA.

The tonnage figures vary depending on the source. For this article, I'll use statistics from DHL’s website.

DHL estimates that each team transports an average of 50 tons of cargo per year, which can cost over 8 million dollars. The cargo travels approximately 80,000 to 90,000 miles per season, depending on the race calendar. In 2023, a total of 1,400 tons of goods were transported throughout the season.

Up to 6–7 Boeing cargo planes may be used for a single event.

In Europe, the F1 series always uses road transport.

For example, around 300 trucks move from one race to another in Europe. If these trucks were placed in a row, they would form a line over 3.11 miles long.

Logistics involve more than 100 people, including 35 specialists from DHL at each race.

Each team has about three pallets of primary cargo. This is the first shipment that arrives at the circuit, allowing teams to start setting up the cars and pit facilities.

The logistics provider equips its entire fleet dedicated to F1 events with 5G data upload systems and GPS to monitor fuel consumption and choose the best routes. It is increasingly using sea freight and replacing Boeing 747 cargo planes with 777s, which are 18% more fuel-efficient.

While AI is not used in this operation, I found an article that mentioned an efficient optimization program called C3, which manages logistics companies' bookings, schedules, routes, and overall operations. (Source: C3 Solutions Blog)

I find it interesting, from an emissions perspective, that mid-season races are held in Italy and Monaco, followed by a shift to Canada for the Canadian Grand Prix, after which the remaining European races take place.

Here is the 2025 calendar from Formula1.com

F1 Series’ Plan for Reducing Emissions

"The engines don’t sound right, and reducing emissions makes the sport less exciting" has been one perspective from a segment of fans regarding sustainability. Fortunately, times are changing.

In 2019, the F1 series set itself a strategy:

• Achieve net-zero emissions by 2030

• Leave a positive legacy everywhere

• Build a more diverse and inclusive sport

In 2026, the F1 will transition to usage of 100% renewable fuel.

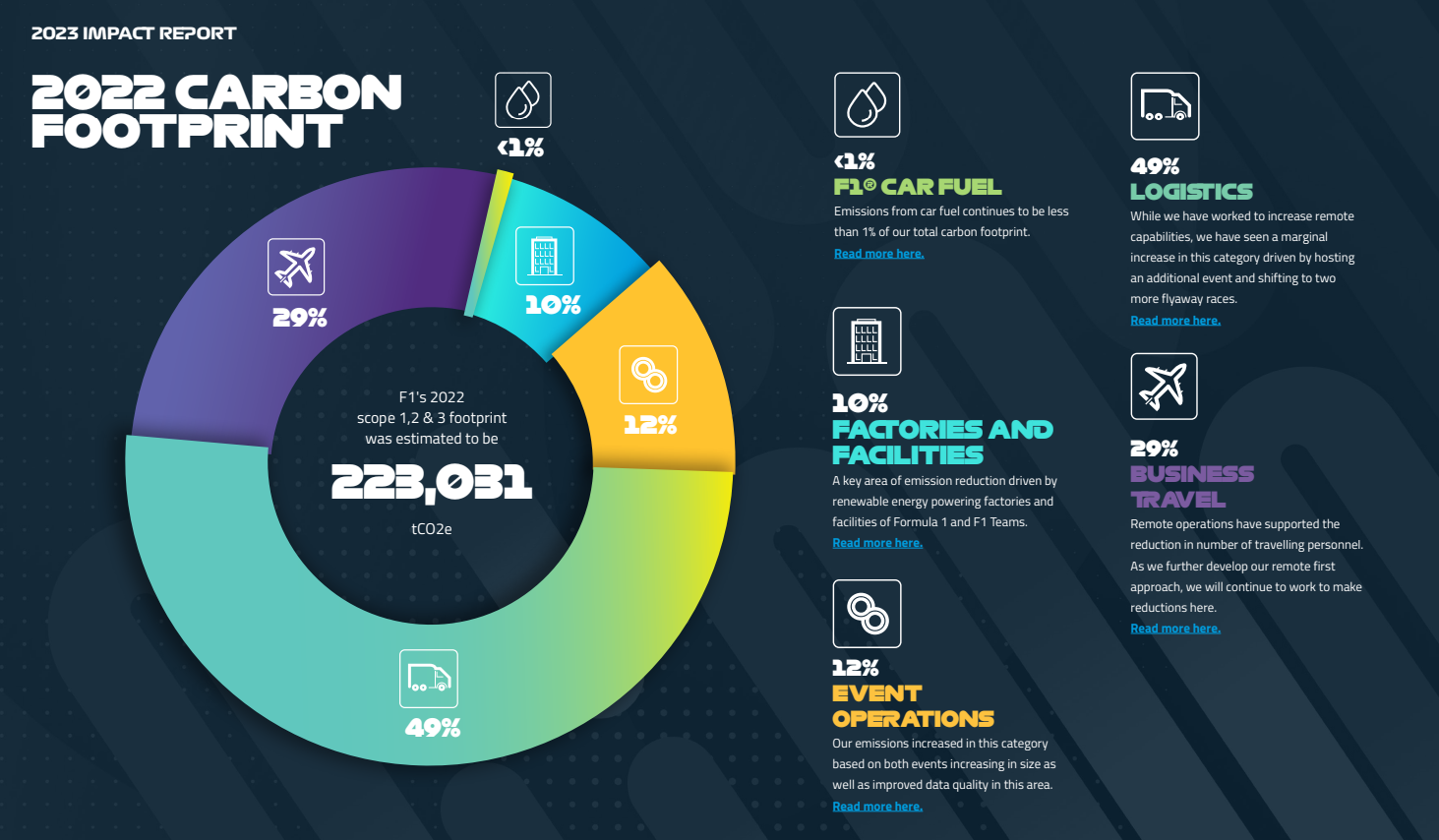

In 2022, the series' emissions totaled 223,031 tCO2e.

F1 has done a great job in recognizing that they cannot drive this change alone by mapping out their key stakeholders: FIA, F1 teams, race promoters, commercial partners, media companies, original engine manufacturers, key suppliers, and fans.

Here is an image of F1’s carbon footprint:

Real actions have already been taken in the series:

The Austrian Grand Prix reduced emissions by over 90% in the pit lane, paddock, and broadcast center with a new energy management hub.

The Bahrain International Circuit’s solar power plant produced 5.28 MW of clean energy between the 2022 and 2023 Grand Prix races – enough renewable energy to cover the entire F1 track’s usage, with plenty of surplus capacity.

The British Grand Prix ran entirely on green energy, including the use of 2,746 solar panels. Temporary generators used renewable diesel.

Other measures include reducing personnel, equipment, and traveling distances.

One of the series' biggest challenges is to create a credible offsetting strategy for 2026–2030.

I think this is something that all companies will have a challenge of overcoming.

You can read the 2023 Formula 1 Impact Report here:

Formula 1 Impact Report 2023

Join over 14K+ subscribers to get the latest freight news and entertainment directly in your inbox for free. Subscribe & be sure to check your inbox to confirm (and your spam folder just in case).